Helicopters, Ground Anchors, and Smart Design: Overcoming Remote Construction Challenges in Marlborough Sounds

- ziliamagdeeva

- Mar 4

- 3 min read

How do you build in a place with no road access, no jetty, and no easy way to transport materials? That was the challenge our team faced in Kenepuru Sound, Marlborough, South Island, where a remote construction site required a creative approach to logistics, design, and sustainability.

With materials needing to be flown in by helicopter, traditional construction methods simply weren’t practical. Instead, DTCE developed a solution that reduced material transport while ensuring structural integrity.

In this blog, we’ll take you through the unique challenges of this project, the engineering solutions we applied, and how we successfully delivered a design suited for such an extreme location.

Project Background

In 2022, severe rain events and subsequent landslides caused significant structural damage to a residence in Kenepuru Sound. The building's foundations experienced lateral and minor vertical movement, compromising the structural integrity of the house and deck foundations. Working closely with S.J Contracting builders, our goal was to design and implement a robust repair strategy to restore and enhance the building's stability.

Smart Design for a Challenging Location

Our team had to think outside the box from the outset. Transporting materials posed a significant challenge —so much so that the builder had to construct a helicopter landing pad just to fly in supplies! Knowing this, our team had to consider this during our design to limit the amount of materials that needed to be shipped in.

Key Engineering Decisions:

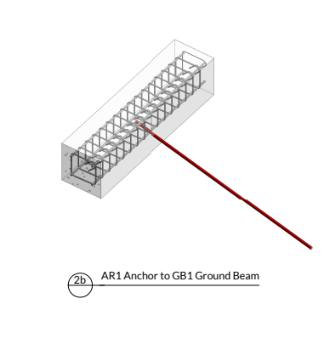

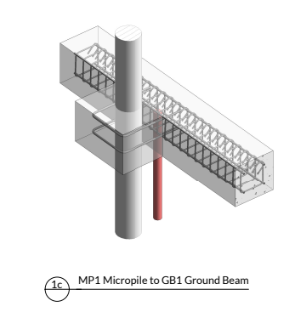

Minimising Concrete Use: Traditional augured concrete piles were not a viable option due to the difficulty of transporting large quantities of concrete. Instead, we used ground anchors and micropiles, which provided the necessary foundation support while significantly reducing concrete requirements.

Structural Stability: The site had suffered damage due to landslides and heavy rainfall events in 2022. To stabilise the structure and prevent future movement, we incorporated ground beams, micropiles, and soil anchors to reinforce the house’s foundation.

Subfloor Bracing: The existing subfloor braces were insufficient given the site’s high wind loads and earthquake considerations. We implemented new subfloor braces to provide the necessary lateral support.

Deck Reconstruction: The existing deck, severely damaged and deemed beyond repair, was completely redesigned. The new deck features foundations anchored to firm soil, with diagonal braces connecting deck posts to the existing house piles, ensuring both vertical and lateral stability.

I3D Indicative Visualizations Visualization

Engineering for Sustainability & Efficiency

Every design choice balanced efficiency, sustainability, and practicality. Our approach reduced environmental impact by minimising material transport while ensuring the structure’s resilience in an exposed and challenging environment.

The design adhered to NZ building standards, considering dead, live, wind, and earthquake loads to create a robust and code-compliant solution.

Lessons Learned: The Value of Proactive Planning

At DTCE, we are committed to delivering engineering solutions that blend innovation with practicality, ensuring our clients' projects stand the test of time.

In Conclusion

Every design choice balanced efficiency, sustainability, and practicality. Our approach reduced environmental impact by minimising material transport while ensuring the structure’s resilience in an exposed and challenging environment.

For insights into how remote construction monitoring can lead to significant cost savings, explore our recent blog post:

Need an engineering solutions for your next project?

Whether your project is in the heart of the city or tucked away in a remote location, DTCE’s experienced team is ready to help.

Get in touch with us to discuss how we can support your structural design needs.

Comments